New Facing Targets Sputtering System

Overview | Features | Principle | Applications | Product Information

NFTS Applications

NFTS Technology Fields | Low Temperature Crystallization | Mass Production | Performance | TEM Images | Publications

Difference of Low E coating films produced by MS

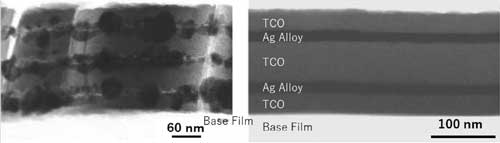

In order to investigate the difference of thin film structures in detail, these films were observed under TEM (Transmission Electron Microscope). The below images show a cross sectional view of the 5 layers film specimen produced by NFTS and the commercialized 7 layers film by MS. The boundary zone at the interface between the 10nm thick Ag alloy thin layers and the 30 60 nm thick TCO layers (5 layered specimen by NFTS) were continuous and homogeneous. On the other hand, the boundary regions between the 10nm thick Ag alloy layers and the 30 70nm thick oxide thin layers (7 layered specimen by MS) were observed to be partially agglomerated in Ag particles to the size of over 30 nm in diameter or partially disappeared in Ag alloy layers. A unique plasma confinement process of plasma free condition near the substrate surface contributes the reason why the layers prepared by NFTS were smoothly formed on the PET films.

Cross-sectional TEM Images of Low-E coating films

As explained before, NFTS technology has some superior properties in quality and productivity compared to conventional magnetron sputtering technology. And we confirmed these superior points for producing high performance low E coating films with compact NFTS web coater type equipment and comparing with commercialized ones. Moreover, we have developed in line, stationary substrate and rotary substrate types of NFTS equipment in order to satisfy a variety of customer needs. Please feel free to contact us if you would like to know more about our NFTS technology or how we can satisfy your company's needs.