New Facing Targets Sputtering System

Overview | Features | Principle | Applications | Product Information

NFTS Applications

NFTS Technology Fields | Low Temperature Crystallization | Mass Production | Performance | TEM Images | Publications

Production of high performance low-E coating films by web-coater type NFTS equipment

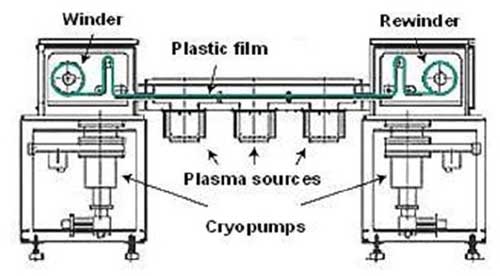

As previously mentioned, NFTS technology make it possible to produce highly qualified thin films at low temperature and low plasma damage compared with CMS. Furthermore, this technology realizes both stable sputtering plasma confinement for long terms and compact equipment for wide area coating compared with CFTS. In order to fully utilize these superior points of NFTS technology, we have developed a web coater type NFTS equipment for producing 100cm width low emissivity (low E) coating films as shown in Fig.6. The low E coating films consist of multilayer of oxide thin films and Ag alloy thin films. These films highly penetrates visible light, reflect almost infrared light and absorb ultraviolet light. As a result, the films contribute to the suppression of heat (infrared light) through windowpanes of automobiles and buildings. For this reason, the low E films have been attracted by increased interests from clients seeking ecological and energy saving products. The performance of the low E coating films produced using a roll to roll type NFTS equipment is explained in comparison with some commercialized samples produced by MS technology.

The properties of web coater type NFTS equipment for mass production

The above figure is a schematic diagram of the 100 cm width web coater with 3 box shaped NFTS plasma sources. The middle of them consists of Ag alloy targets and the others have TCO (transparent conductive oxide) targets. Both, the Ag alloy and the TCO plasma sources have rectangular targets of 12 x 130 cm in size. A major difference from conventional web coater equipment with MS cathode is that the NFTS equipment does not require a cooling drum for deposition zone. This is because NFTS technology makes it possible to strongly confine secondary electrons inside of the box shaped plasma space. Therefore, large increase in substrate surface temperature is prevented without using a cooling drum for the sputtering plasma zone. As a result, a far more compact vacuum chamber and an easy film conveyance system have been realized. From these technologies, the web coater type NFTS equipment realizes superior performance in cost, space and maintenance compared with conventional web coater equipment.